BCAR A8-21 Design and Production

Having an A8-21 approval allows us to ensure regulatory compliance, safety, historical accuracy, engineering excellence, and ongoing operational viability, in accordance to the standards set out by the governing Civil Aviation Authority. This approval underpins the quality and reliability of the restoration work, preserving the legacy and functionality of these treasured aircraft.

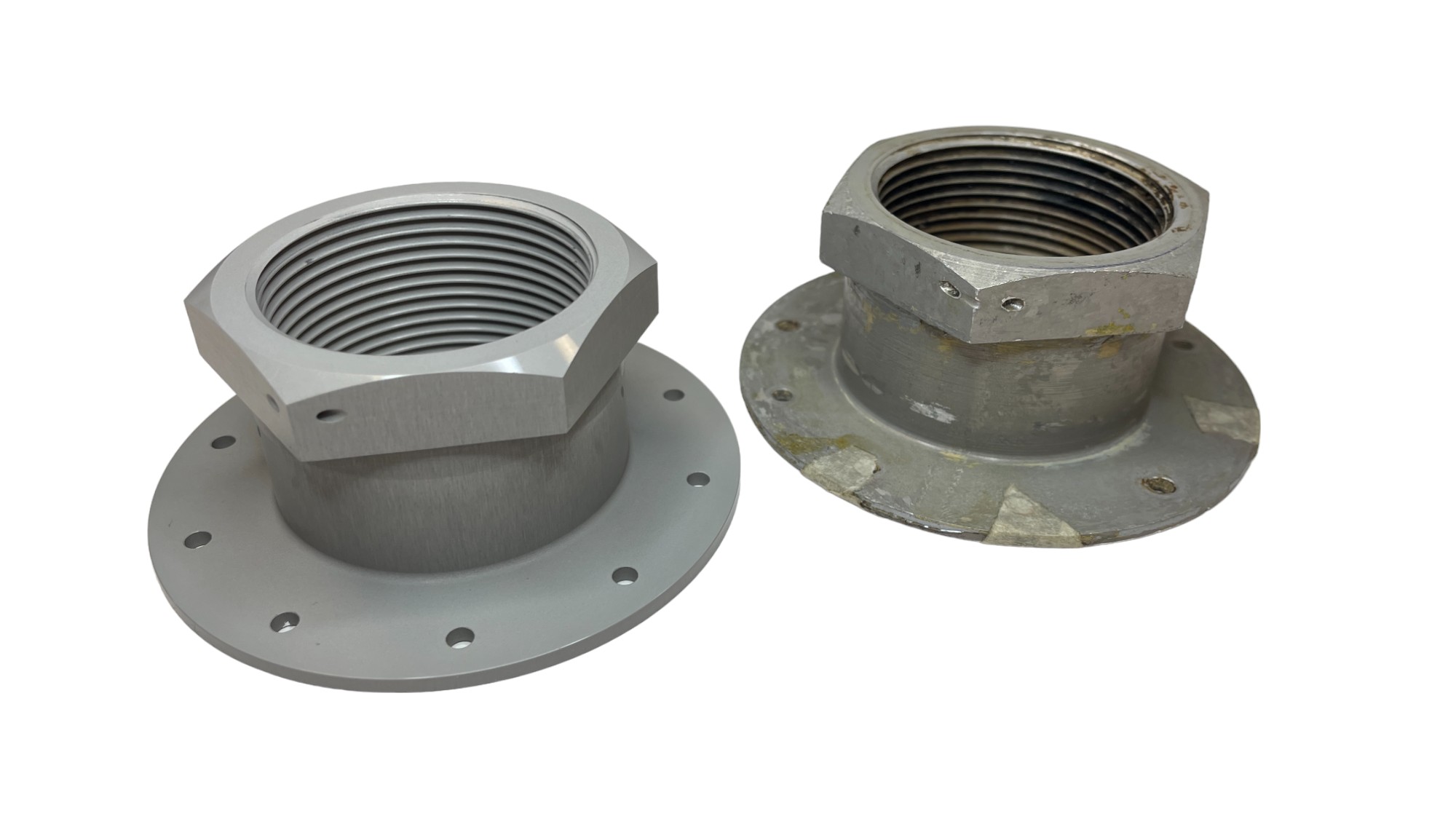

Our designs go through rigorous checks to ensure suitability for the part’s function. An appropriate, justified, and approved material is selected for each part we manufacture, and is released with a UK CAA Approved Certificate to identify the airworthiness status of the aircraft component in relation to the work that has been certified.

Not only limited to aerospace, we can take on any reverse engineering tasks, create a drawing, and re-manufacture them with an appropriate release form, ready to fit to your aircraft/vehicle. Contact us now to enquire.

Manufacturing Capabilities

At Kennet Aviation, we pride ourselves on our state-of-the-art CNC machinery, diligently maintained to meet modern industry standards. Our cutting-edge facilities are designed to handle a wide range of manufacturing tasks with unparalleled precision and efficiency, ensuring each project is completed to perfection.

We operate 3 main CNC machines, providing us with 3, 4, and 5-axis capabilities:

HAAS Super Mini-Mill

Mazak VCN-530C

Mazak CV5-500

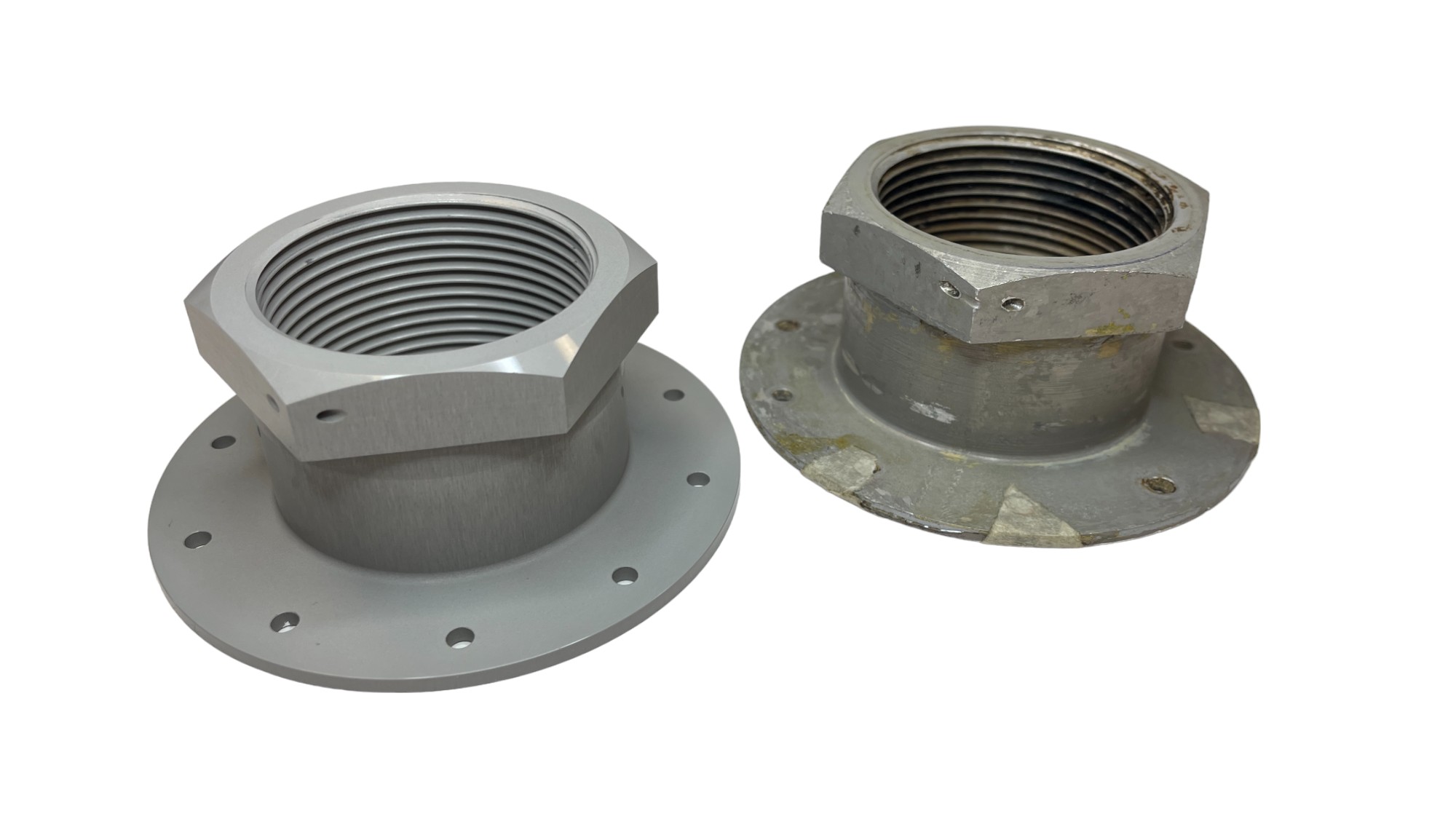

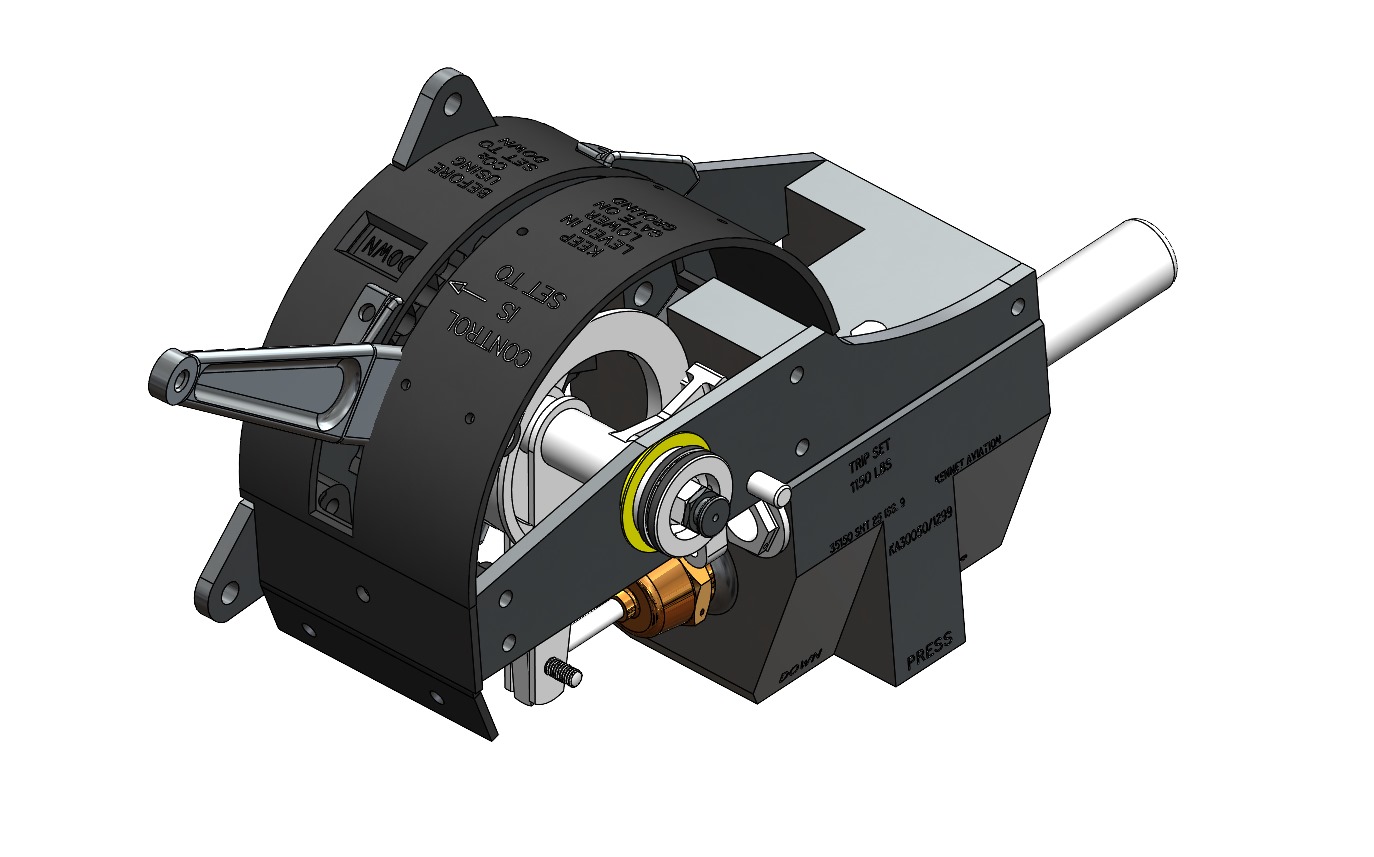

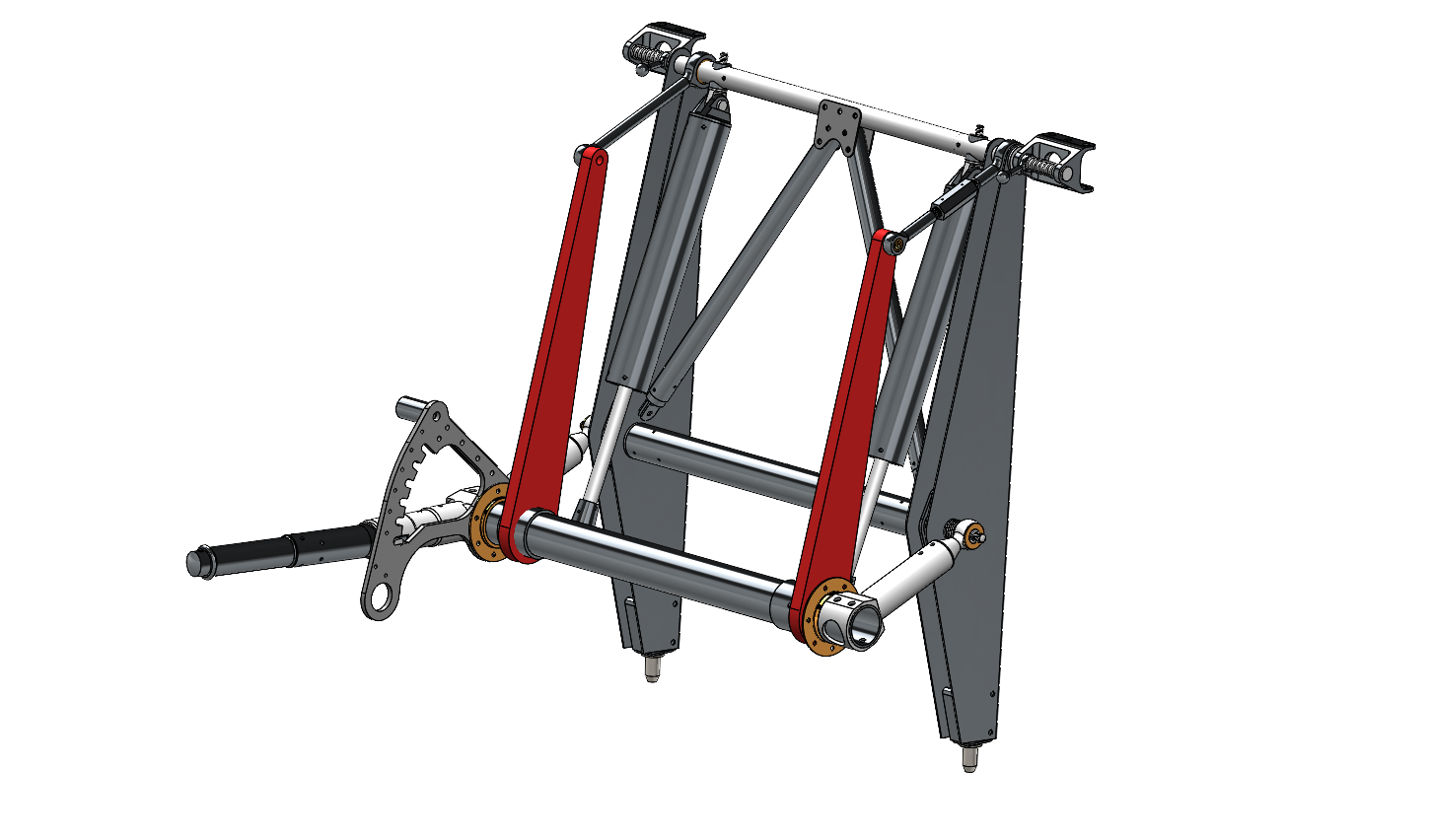

Examples of our CAD and Production Work

To view our A8-21 Approvals and Certificate, visit this page.